The Milk River Drainage Improvement Project is being undertaken to improve reliability and performance and to update aging infrastructure. Rotor Electric of Michigan, LLC was selected by general contractor Spence Brothers to perform all of the electrical work for the $33 million project.

Milk River CSO RTB

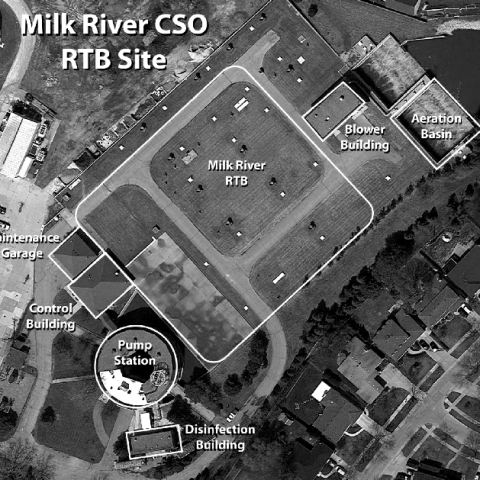

This extensive project requires upgrades to the Milk River Combined Sewer Overflow Retention Treatment Basin (CSO RTB), the Milk River Pump Station, and the Milk River Recirculation Facility. Specifically, the project aims to improve operator controls, basin cleaning, and the recirculation pumping system, as well as rehabilitate aging equipment and the storm water pumps.

The Milk River CSO RTB includes a number of individual facilities, many of which house equipment and components that have exceeded their useful lives. These include:

- Sanitary Pumping Facilities

- Storm Water Pumps

- Retention Treatment Basin

- Aeration Basin

- Blower Building

- Control Building

- Maintenance Garage

- Recycle Pump Station

- Intake Pipe

- Force Main

Storm Pumps and Pump Station

Milk River has seven storm water pumps capable of pumping up to 862,000 gallons per minute (GPM). These pumps range in size from 60-inch pumps to 72-inch pumps. Storm pumps are used to reduce the hydraulic grade (pressure/level) within the sewer system. When needed the pumps operate by pumping to the RTB for storage and possible treatment.

Due to the age of the pumps and their critical role in water processing, the Milk River Intercounty Drain Drainage District (MRIDDD) made the pump repairs the top priority. In addition to updates, the Recirculation Pump Station is adding new mussel control equipment, improving communication and monitoring systems, and replacing the screening equipment for lake intake water.

Force Main Repair

A force main is a pressurized sewer pipe that conveys wastewater in a situation where gravity sewage flow is not possible. Pumps or compressors push the sewage through the force main from lower to higher elevations or across landscapes where deep excavation is not feasible.

A 42-inch force main under the Milk River provides water from Lake St. Clair to the head of the Milk River Channel to improve water quality of the river. Inspections determined that there is a pipe break that will require excavation and repair as part of this project.

Rotor???s Role

Chief among Rotor Electric???s responsibilities for this project was replacement of the primary switchgear while keeping the plant operational. This includes connecting the storm pumps to temporary medium voltage starters to allow room for installation of the new 2000A main-tie-main switchgear lineup and motor control center.

Schedule

Work began in fall 2016 and is scheduled for completion in November 2019.

History and Operation

The MRIDDD was established in 1908 under the Michigan Drain Code. The District’s facilities accept storm drainage from the cities of Harper Woods and St. Clair Shores and combined sewage from the city of Grosse Pointe Woods.

Enclosed drains transport these storm water and combined sewage flows to the Milk River RTB facility where it is pumped into Wayne County???s Northeast Sewage Disposal System. During wet weather events, flows may be pumped into the RTB for storage. If the capacity of the RTB is exceeded during major wet weather events, flows are screened, settled, skimmed, and disinfected before being discharged into the Milk River. A recirculation facility is also utilized to seasonally pump lake water from Lake St. Clair to the outfall of the Milk River RTB to increase dissolved oxygen levels in the river.

MRIDDD facilities are operated by Wayne County. The MRIDDD is managed by the MRIDDD Drainage Board.